Consideration of rheological processes during the welding of plastics by means of numerical simulation and microscopic analyses

Authors: Dipl.-Ing. Norbert Bunk, Prof. Dr.-Ing. Jens-Peter Majschak, M. Sc. André Hüllmann, Prof. Dr.-Ing. Michael Gehde

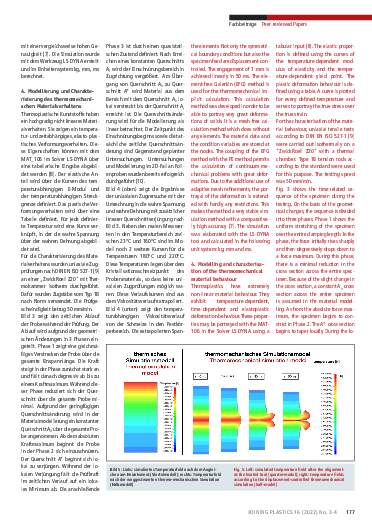

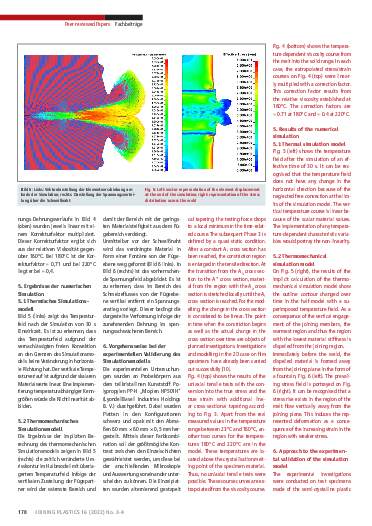

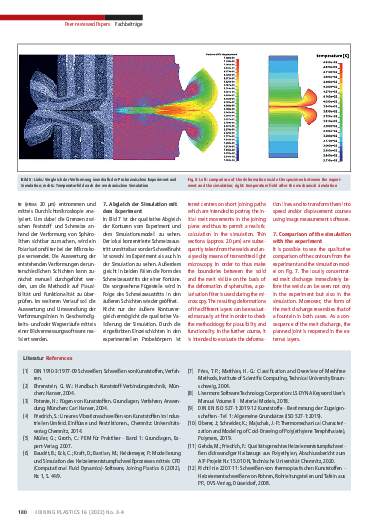

The present paper investigates analysis methods with regard to the time-related course of the melt flow during the welding of thermoplastic components and estimates the analysis potentials. In the analytical approach, the test specimens are manufactured layer by layer in the sequential injection moulding procedure with alternating colouring of the material. In particular, the sharp transition edges between the different colour layers provide information about the deformation and the flow across the plate thickness. The potentials of numerical simulation are presented too. With the aid of the Lagrangian meshing of the geometrical test specimen using remeshing, maximum degrees of deformation can be represented in the simulation. Because it is not possible to show the numerical image of the phase transition, investigations are conducted into the limits of the temperature-dependent structural-mechanical material model.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription