Effects of different heating strategies on the quasi-static and cyclic load-bearing capacities of infrared-welded, glass-fibre-reinforced thermoplastic components

Authors: M. Sc. Karina Gevers, M. Sc. Lucas Schraa, M. Eng. Paul Töws, Prof. Dr.-Ing. Volker Schöppner, Dr.-Ing. Kai Uhlig, Prof. Dr.-Ing. Markus Stommel, M. Eng. Julia Decker

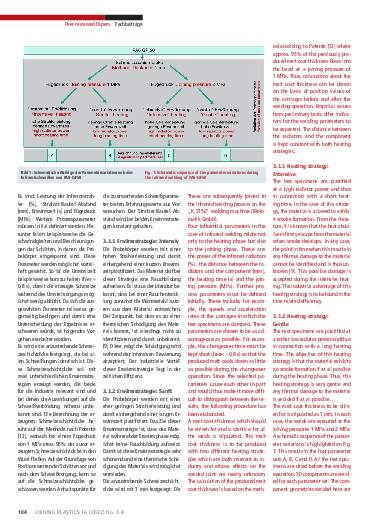

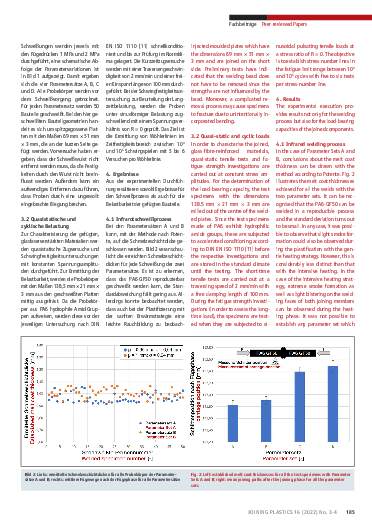

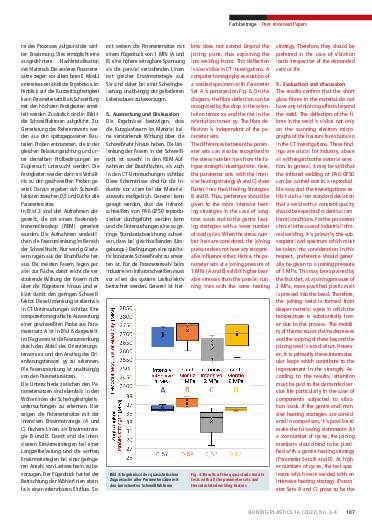

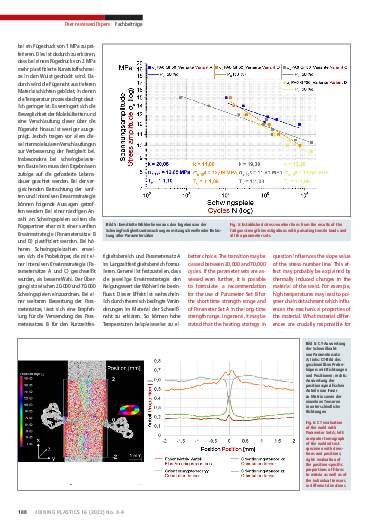

Infrared welding is one of the changeover, contactless joining procedures and is therefore extremely suitable for the welding of technical thermoplastics. In this respect, the material is plastified by radiation. Above all, the welding parameters and thus the heating strategy can be defined in different ways since not only gentle heating but also intensive heating exhibit individual advantages. Here, preference can be given to economic advantages such as time-efficient welding or a variant which goes easy on the material. These diverse strategies exert significant effects on the mechanical load-bearing capacity. In this case, different approaches to infrared welding can be preferred depending on the load case. This connection has been discussed in the investigations and it was possible to elaborate recommendations for action for the infrared welding industry.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription