Weld peculiarities of infrared-welded joints between laser-sintered and injection-moulded components

Authors: M. Sc. Michael Wolf, Prof. Dr.-Ing. Dietmar Drummer

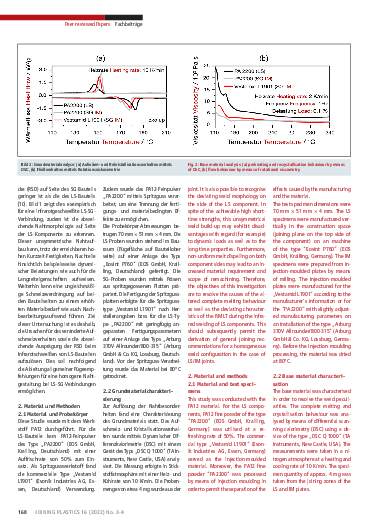

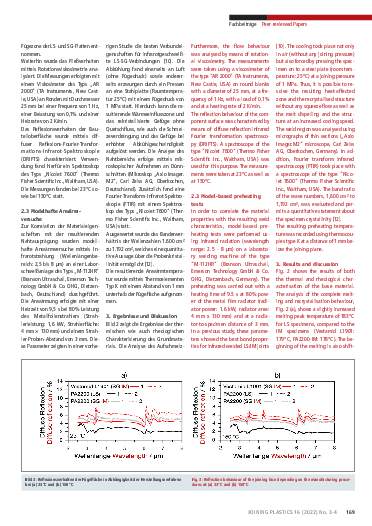

Joining procedures are required for the complete exploitation of additive manufacturing. In this respect, welding permits a high bonding quality with welding factors up to 1.0. However, it is conspicuous that the weld build-up deviates from the

literature in the case of welded joints with laser-sintered components. In addition to an altered morphology, the heat-affected zones and residual melt thicknesses of infrared-welded laser-sintered components are enlarged considerably, compared to injection moulded components. Withthe aid of the investigations, it was possible to resolve the causes of this and to derive joining recommendations in order to attain uniform melt dispelling on both component sides. Furthermore, the analyses show that the component crystallinity which is clearly different in the base material is equalised in the weld region.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription