Infrared welding in tempered ambient conditions

Author: Dipl.-Ing. Wolfgang Kazmirzak

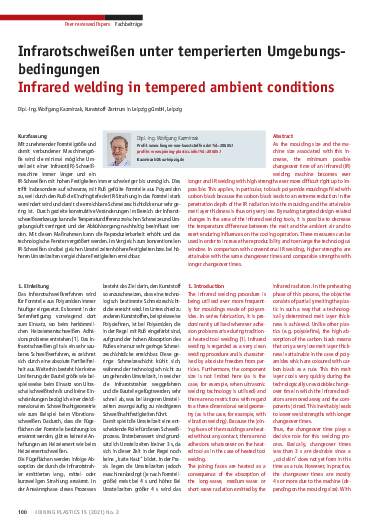

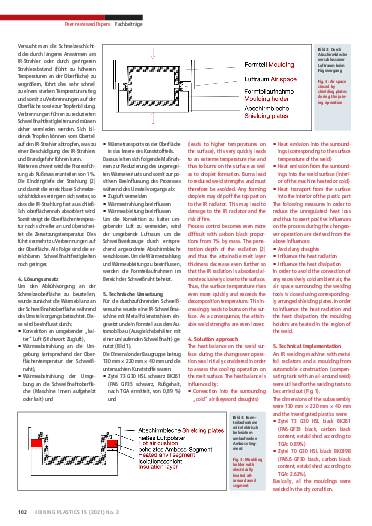

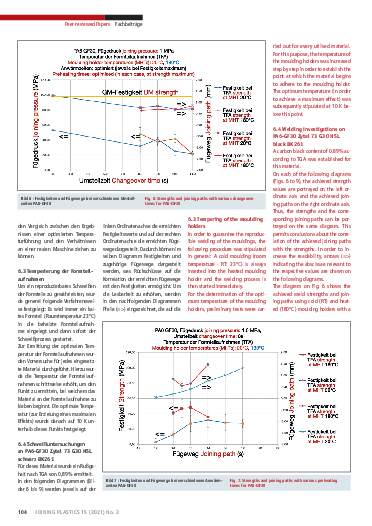

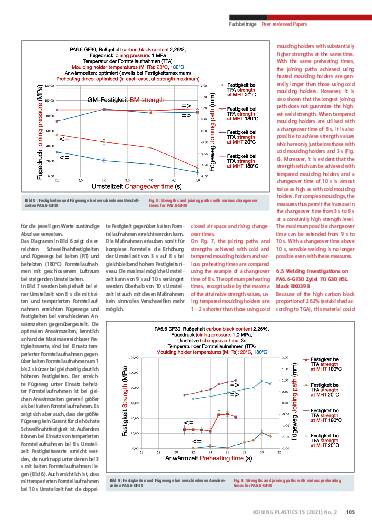

As the moulding size and the machine size associated with this increase, the minimum possible changeover time of an infrared (IR) welding machine becomes ever longer and IR welding with high strengths ever more difficult right up to impossible. This applies, in particular, to black polyamide mouldings filled with carbon black because the carbon black leads to an extreme reduction in the penetration depth of the IR radiation into the moulding and the attainable melt layer thickness is thus only very low. By making targeted design-related changes in the area of the infrared welding tools, it is possible to decrease the temperature difference between the melt and the ambient air and to exert enduring influences on the cooling operation. These measures can be used in order to increase the reproducibility and to enlarge the technological window. In comparison with conventional IR welding, higher strengths are attainable with the same changeover times and comparable strengths with longer changeover times.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription