Investigations into the utilisation properties and procedural limits of thermal direct joining

Authors: M. Sc. Julia Schoft, Dr.-Ing. Kira van der Straeten, Prof. Dr.-Ing. Uwe Reisgen, Dr.-Ing. Alexander Schiebahn

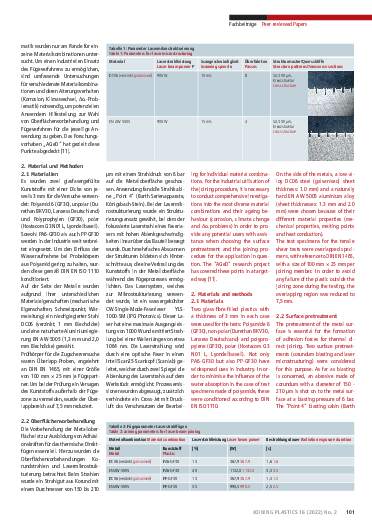

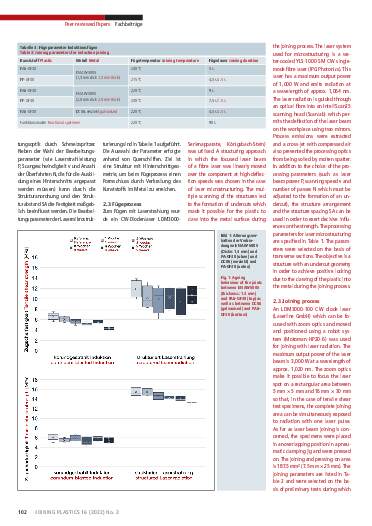

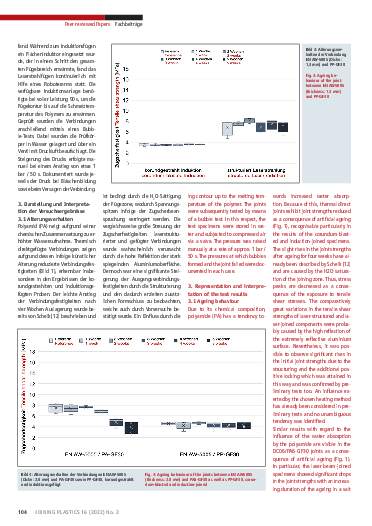

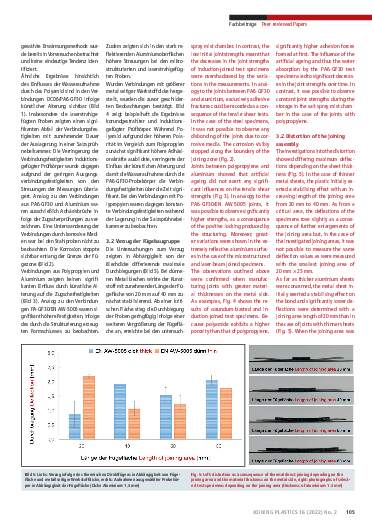

Thermal direct joining offers a very promising approach to the joining of thermoplastics and metals. In spite of reproducible joint formation, the path into industrial application frequently failed due to the lack of a knowledge basis about the utilisation properties and limits of this joining procedure. Therefore, the “AGeD” project focused (amongst other subjects) on the ageing behaviour, the leak tightness of the joints as well as the development of distortion as a consequence of the joining process. It is possible to observe that the joints are not only airtight up to 5 bar in principle but also exhibit stable ageing behaviour. The limits of thermal direct joining relate to the joinable area. Depending on the geometry and thermal expansion behaviour of the joining parts, shrinkage stresses cause distortion during the cooling phase.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription