Thermal riveting of polymer materials - Computer- aided process modeling and comparison with experimental data

Authors: Dr.-Ing. Eric Brückner, Prof. Dr.-Ing. Sebastian Härtel, Prof. Dr.-Ing. Michael Gehde, Univ.-Prof. Dr.-Ing. habil. Dipl.-Math. Birgit Awiszus

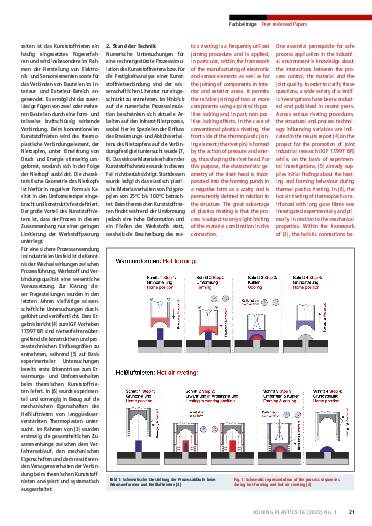

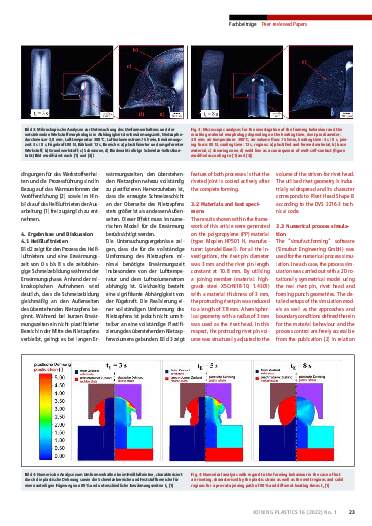

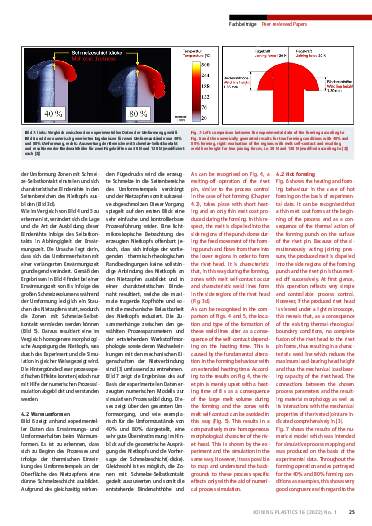

In the case of thermal plastics riveting, the application of precise, computer-assisted process simulation does not correspond to the state of the art at present. For this reason, the structural configuration of the joint is primarily based on subjective experience values and empirical tests on the (series) component. Within the framework of a project which is being promoted by the German Research Federation (DFG) and carried out at the Chemnitz University of Technology, it is intended to close these gaps by developing numerical models for the heating and forming behaviour of thermal riveting processes, i.e. hot forming and hot air riveting. The present article summarises the scientific investigations from [1], [2] and (in excerpts) [3] in a compact form and shows the, as yet, first numerical models for real plastics riveting processes taking account of realistic material and process conditions. The results of the numerical simulations un-til now show great congruence with the experimental data. In the future, the possibilities of computerassisted process simulation might provide a uniform planning and designing tool and thus simplify the component and process configuration to a great extent.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription