Laser welding of polymer foils with spatially adapted intensity distributions

Authors: M. Sc. Frederik Maiwald, M. Sc. Lea Kroth, Dipl.-Ing (FH) René Geiger, Dr. Bernhard Schmitt, Prof. Dr.-Ing. Stefan Hierl, Prof. Dr.-Ing. Michael Schmidt

DOI: https://doi.org/10.53192/JP20250146

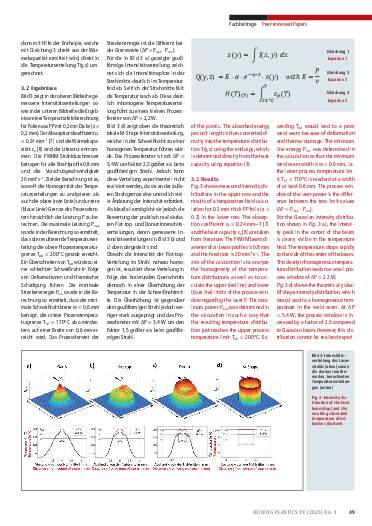

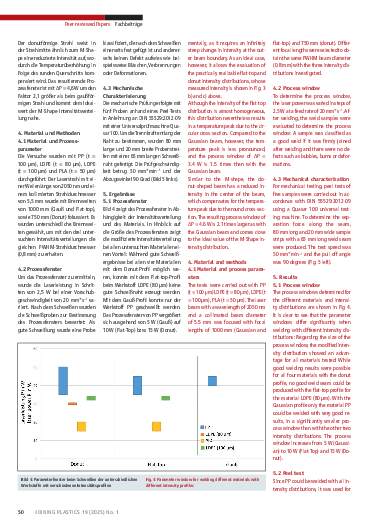

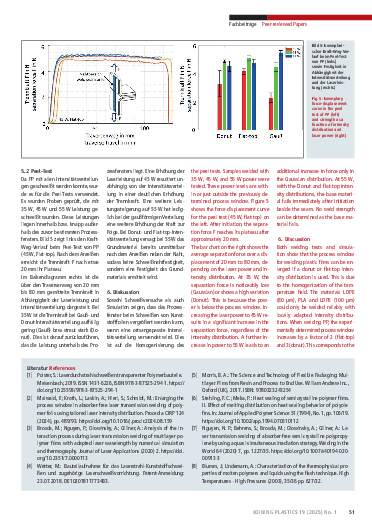

Absorber-free laser transmission welding is characterized by its contactless energy input and geometricflexibility and enables the precise and clean joining of polymer films without absorbing additives or adhesives. It is therefore well suited for applications with high demands regarding process reliability and cleanliness such as packaging, fluid containersor as sealing film in medicaland food industry. A homogeneous weld seam temperature is necessary for a large processwindow. In this work, the naturally Gaussian-shaped intensity distributionof the laser beam is there foreconverted into a donut-shaped and a flat-top-shaped distribution. When using the donut-shape, the processwindow for welding polypropylene or polyethylene films is increased by up to a factor of 3. At the same time, the weld seam strength almost corresponds to the strength of the base material.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription