Long-term properties of butt fusion welds on gas pressure pipes made of unplasticised Polyamide 12

Authors: Dr.-Ing. Ruben Schlutter, Dipl.-Ing. Dipl.-Wirt.Ing. Britta Gerets, B. Sc. Tobias Eckhardt, Dr.-Ing. Gernot Hochleitner, Dr. Eduard Kraus, Prof. Dr.-Ing. Martin Bastian, Dipl.-Ing. Hermann van Laak, Dipl.-Ing. Jochen Fritz

DOI: https://doi.org/10.53192/JP20240129

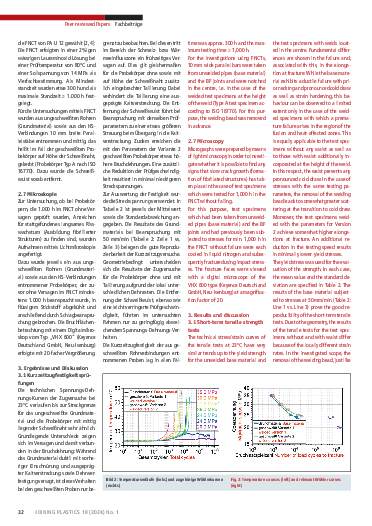

The unplasticised Polyamide 12 (PA-U 12 ) “Vestamid NRG 2101 ye” (ye stands for yellow) (Evonik Operations GmbH, Marl) is a PA-U 12 180 certified for pipeline construction according to ISO 16486-1, ISO/TS 16486-7 and DVGW GW 335 . In gas distribution, this polyamide compound offers an alternative to steel above polyethylene (PE-HD) for pressures up to 16 bar. In this respect, the maximum operating pressure of 18 bar has been reduced to 16 bar by CEN for pipes with a wall thickness to outer diameter ratio (standard dimension ratio, SDR) of 11. For underground gas pipeline systems and overground industrial pipeline systems, the normative prerequisites for utilisation are being created at present [1]. Here, attention is currently focusing on the long-term properties of the welded joints in particular.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription