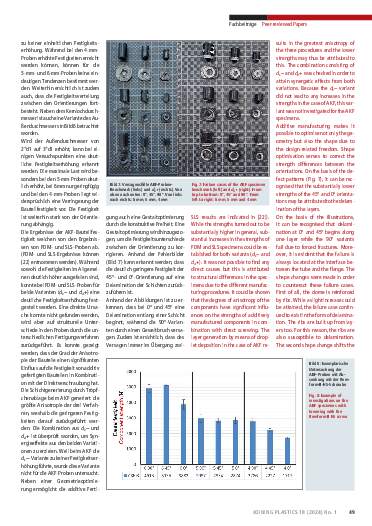

Geometry design to increase the short-term strength of direct screw connections in additively manufactured plastic components made of PA12

Authors: Prof. Dr.-Ing. Elmar Moritzer, M. Sc. Christian Held

DOI: https://doi.org/10.53192/JP20240144

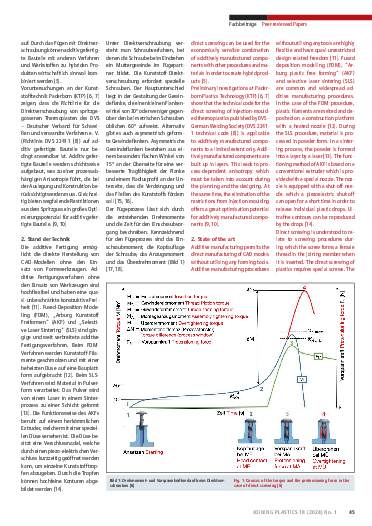

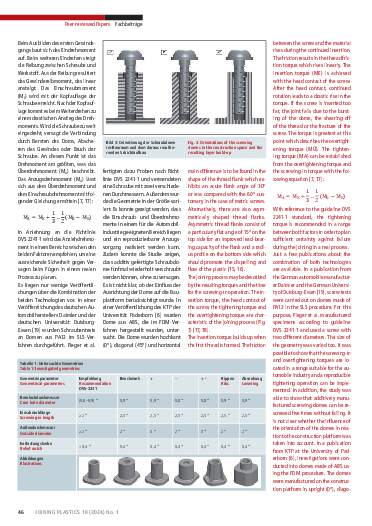

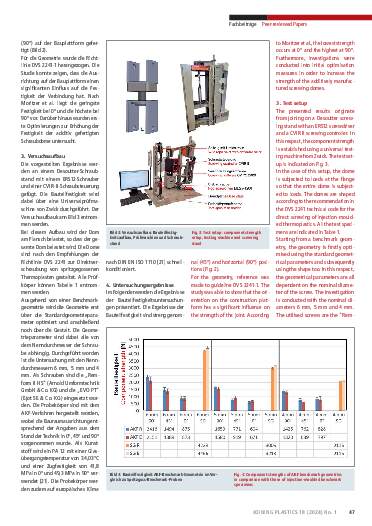

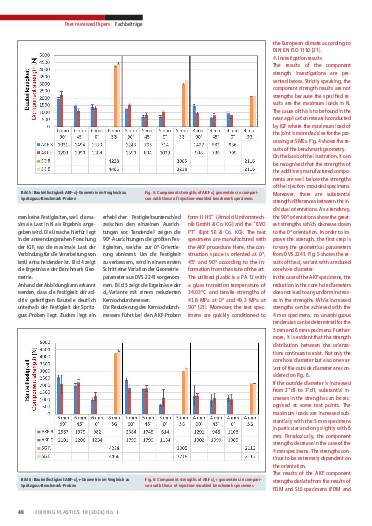

Additive manufacturing is a widespread standard in prototype construction in particular and is characterised by the high degrees of design-related freedom and flexibility. Disadvantages are to be found in the long manufacturing times and the overproportional ratio of the costs to the construction space size. Direct screwing can be used for the economically sensible combination of additively manufactured plastic components with other components in order to create larger or hybrid products. Unlike injection-moulded components, there are no guidelines for the direct screwing of additively manufactured components. Against this background, the suitability of additively manufactured components for direct screwing is being checked and optimised in AIF-IGF Project 21.902 N in order to elaborate recommendations for the configuration and the application. In this publication, the determination of the mechanical parameters is explained using the example of Arburg plastic free forming.

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription