Injection riveting for the joining of thermoplastic composites with metal parts

Authors: Prof. Dr.-Ing. Elmar Moritzer, M. Sc. Dimitri Krassmann, M. Sc. Johannes Brikmann

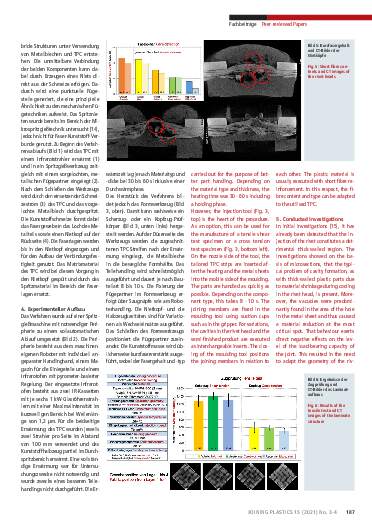

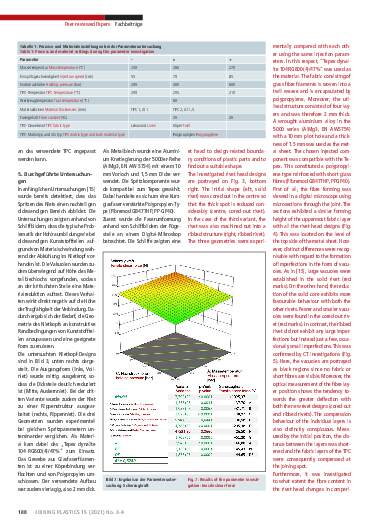

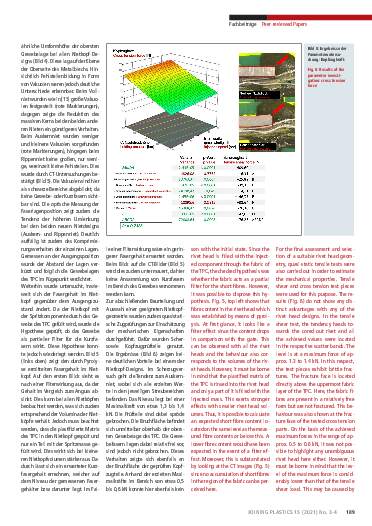

Hybrid technology is a widespread procedure variant of injection moulding for the joining of plastics and metals. This also applies to the procedure variant called “hybrid moulding“ which makes direct use of forming and back-moulding in order to process thermoplastic composites (TPCs) and composite materials into high-strength components. For the combination of both technologies, the addition of injection riveting made it possible to develop a procedure which constitutes a joining technology by forming rivets during the through-injection of TPCs and preperforated metal components. In this respect, the joint is designed in such a way that the TPC is pulled into the metal component by the melt flow but the fibre structure is not damaged. The joining technology was characterised within the framework of a research project at Kunststofftechnik Paderborn (KTP).

An active subscription enables you to download articles or entire issues as PDF-files. If you already are a subscriber, please login. More information about the subscription